What is Keymark?

Keymark is a voluntary third-party product certification mark demonstrating users and consumers that the products bearing it are in conformity with the requirements set forth in standards published by CEN/CENELC. This is ensured by means of a certification process including: conformity tests (initial type testing), assessment of the factory production documents for every production line and, finally, factory inspection. Keymark is a mark awarded by CEN SDG-5 through Empowered Bodies and the relevant Registered Laboratories that in Spain are AENOR and ceis, respectively.

Background

In the light of the publication in 2002 of harmonised product standards for thermal insulation products for buildings, integrated within the Construction Products Directive, current Construction Products Regulation (EU) No. 305/2011 (CPR), it became mandatory for manufacturers to conduct tests to comply with the regulatory CE Marking required by it. To this end, manufacturers had to conduct a series of tests in order to characterise the products manufactured according to a series of minimum properties laid down. This way, the certified product could move freely across the European Union. Besides, member countries could demand another series of minimum characteristics by means of their national voluntary certification marks. Keymark was the result of an agreement reached by the European insulation industry as a whole to prevent this kind of conflicts.

Focusing on thermal insulation products for buildings, the harmonised product standards and test standards that apply to them were prepared in the past within CEN/TC 88, laying the foundations for the CE Marking of said products and thus proving their compliance with the CPR.

Conformity of products with the CPR (CE Marking) only ensures compliance of thermal insulation products with the minimum legal requirements that basically apply to them depending on their reaction to fire classification, i.e., according to its end use application. (see table 1).

| PRODUCTS | INTENDED USE | LEVELS OR CLASS

(reaction to fire) |

Attestation of conformity systems |

|---|---|---|---|

| Thermal insulation products

(factory made products) |

For uses subject to regulations on reaction to fire |

(A1, A2, B, C)*

|

1

|

|

(A1, A2, B, C)**, D, E

|

3

|

||

|

(A1,to E)***, F |

4 |

||

|

System 1: See CPD Annex III.2.(i), without audit-testing of samples System 3: See CPD Annex III.2.(ii), Second possibility System 4: See CPD Annex III.2.(ii), Third possibility |

|||

*Products/material for which a clearly identifiable stage in the production process results in an improvement of the reaction to fire classification (e.g. an addition of fire retandants or a limiting of organic material).

**Products/materials not covered by foonote (*).

***Products/materials that do not require to be tested for reaction to fire (e.g. Products/materials of classes A1 according to Commission Decision 96/603/EC, as amended).

Table 1: Conformity assessment systems according to the reaction to fire classification

This way, the CE Marking, which is mandatory, only focuses on the essential requirements that products have to comply with, based on the CPR and, therefore, for just a limited number of characteristics, while product certification, which is voluntary, covers all the characteristics defined in product standards.

Bearing in mind that end consumers’ demands go beyond the minimum legal characteristics, the representatives of the European insulation industry prepare their product standards so that manufacturers have the obligation to declare certain specific levels for particular properties.

Keymark provides thermal insulation products with a way of proving their conformity with quality parameters higher than those established by law. Therefore, Keymark goes beyond product conformity with the essential requirements set forth in the CPR. The Keymark conformity declaration procedure provides product certification regarding all the standards requirements and all the product characteristics (properties) declared by the manufacturer complementing the requirements for the CE Marking. This procedure includes third-party tests of the products.

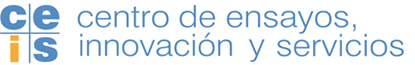

The tasks developed within the procedures set to be awarded the CE Marking are included in the procedures for Keymark certification. The CE Marking procedures only involve the participation of a third party, whereas Keymark certification involves the participation of two third parties.

The Keymark certification scheme was developed by a joint group made up of representatives of the industry, testing laboratories and certification bodies that reached a global agreement within the European insulation industry. This scheme was prepared by the Scheme Development Group SDG-5, set up under the authority of the CEN Certification Board (CCB).

The scheme covers and is applicable to product standards developed within CEN/TC 88, such as standards on thermal insulation products for buildings (EN 13162 to EN 13171), thermal insulation products for industrial installations, in-situ applied insulation products or ETICS. Although it is also applicable to product standards beyond the scope of CEN/TC 88, such as UNE-EN 140631:2006 on expanded clay.

SDG-5

The Scheme Development Group 5 (SDG-5) is the body bringing together manufacturers, laboratories and certification bodies, active in the field of thermal insulation products. It is responsible for drafting the specific scheme rules that apply for Keymarking of thermal insulation. SDG-5 is made up of a series of experts at European level including manufacturers’ representatives, as well as testing laboratories and certification bodies. Apart from developing the regulations governing the Keymark certification, they assess Keymark certificates and award them, if appropriate, they also supervise the different inter-laboratory comparative tests among the Keymark Registered Laboratories, and they study the audit reports of the laboratories applying to become Registered Laboratories, as well as the certification bodies wishing to become Keymark Empowered Bodies so that they can award Keymark certificates together with the relevant national certificates for each country.

Along the lines of SDG-5, there are other Scheme Development Groups such as SDG-1, SDG-2, SDG-3 and SDG-4 that award the Keymark certification to plastics, fire-extinguishers, ceramic tiles and controllers for heating systems, respectively.

Empowered Bodies

Empowered Bodies are certification bodies authorised by CEN to award Keymark certificates together with their own quality mark certificates. In Spain there is an Empowered Body that is AENOR that, together with its N Mark certificates, can award Keymark certificates to those products which successfully undergo the tests required.

In order to become an Empowered Body, certification bodies must be accredited by an accreditation body in conformity with EN 45011. Empowered Bodies are responsible for ensuring the technical expertise of their subcontractors in activities such as product inspection and tests. For instance, in the case of testing laboratories, these have to be accredited according to EN ISO/IEC 17025. CEIS conducts tests for AENOR to this end, since it complies with the aforementioned requirements.

Registered Laboratories

Those testing laboratories wishing to be part of the Registered Laboratories network and, therefore, wishing that their results are valid for the Keymark certification scheme, must meet the following requirements:

- The laboratory shall be accredited by the relevant accreditation body against EN ISO/IEC 17025. In particularly, the laboratory shall be able to demonstrate participation in inter-laboratory comparative testing for thermal conductivity measures. The laboratory shall be notified under the Construction Products Regulation (EU) No. 305/2011.

- The laboratory shall have and prove its experience with test procedures (conditioning, ageing and measuring according to product specifications) according to the specific product standards.

- The laboratory staff and equipment shall comply with the requirements of EN 1946-1, 2 and/or 3 and documentary evidence of compliance shall be retained for the purposes of technical auditing.

- The laboratory shall determine the thermal conductivity of thermal insulation materials at an average temperature of 10 ± 0.3 ºC.

The results provided by the laboratory shall be in keeping with European level λ10 with a margin of ± 1.5 %. This requirement shall be proved by means of participation in inter-laboratory comparative testing organised by SDG-5.

ceis is a Registered Laboratory and as such complies with all the aforementioned requirements.

The relationship there is among the aforementioned bodies and between the CE Marking and the Keymark certification is illustrated in the following figure:

The ceis Thermal Insulators Lab is a Registered Laboratory for the Keymark certificate since 2007. All the aforementioned requirements were verified by an external auditor appointed by SDG-5. Due to its importance, we are going to explain the aspects that were assessed during the audit and the data gathered so that it can be made clear what it means for laboratories to be part of the Keymark scheme and the reliability of the results provided by these laboratories.

Audit for Registered Laboratories: accuracy and uncertainty of results

Of all the aforementioned requirements, the most important one to become a Registered Laboratory is the one carried out at the end which entails successfully undergoing a technical audit focusing on the thermal conductivity test, conducted by a technical auditor appointed by SDG-5. The reference documents upon which this audit is based are the group of standards EN 1946-1, 2 and 3 “Thermal performance of building products and components – Specific criteria for the assessment of laboratories measuring heat transfer properties”. This group of standards establishes specific requirements to accredit the technical expertise of testing laboratories determining the thermal conductivity of thermal insulation products. In particular, part 1 (common criteria) and part 3 (measurements by heat flow meter method) apply to ceis.

In addition to being present when the in-situ test is carried out, verifying the validity of the testing procedures and the experience of the laboratory staff, the auditor conducts a series of verifications on the thermal conductivity equipment which provide the uncertainty data when measuring this parameter. These verifications are the following:

- Evaluation of heat loss at the ends; for this verification the temperature is measured at the ends of a sample of high thickness when it is tested verifying that the temperature ratio factor at the ends, e, is within the limits set forth in EN 1946-3.

- Calibration in temperature; the temperature of the equipment plates shall remain stable and uniform at ± 1 % regarding the average difference of temperature between the top plate and the bottom plate that, in the case of ceis, involves a maximum allowable variation of ± 0.1 ºC.

- Dimensional calibration; two verifications of this type are carried out; on the one hand, verification of the flatness of each plate and of the horizontalness of a plate vis-à-vis the other one, and on the other, verification of how the equipment measures the thickness of the test tubes. In both cases, the equipment meets the limit set forth in EN 1946-3, which is ± 0.5% for both verifications.

- Reference sample; verification of whether the reference sample (necessary to calibrate and verify the equipment, since at ceis work is done with a heat flow meter) is that established by CEN, i.e., IRRM-440 reference material, verifying the validity and period in force of its certificate. Within this same point, the validity of the calibration carried out on the equipment is checked.

- Study of linearity on the equipment’s response; study of how the equipment responds when different samples of the same material and thickness are piled up, carrying out successive tests on different levels of thickness checking that the equipment’s response in terms of the thermal resistance data is linear depending on the thickness. The variation factor was not higher than ± 0.5 %, which was established as the allowable limit, as well as the influence of the contact resistance that takes place when it is necessary to pile up different layers of material to reach the minimum testing thickness.

- Checking the emissivity of the equipment plates; checking that their heat emissivity is not higher than 0.8, as it is set forth in EN 1946-3.

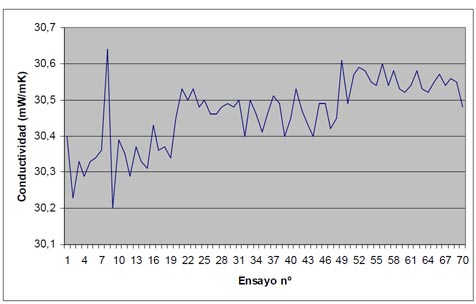

- Reproducibility and repeatability of the equipment, for these data there are maximum variations of 0.40 % and 0.13 %, that may under no circumstances be higher than 1%, which is the maximum allowable limit set forth in test standard EN 12667. In the following figure we can see the data obtained against the IRRM reference sample in the verifications that the equipment is subject to on a fortnightly basis, showing the stability of the equipment. The data have been compiled since 2005 until today.

This brief summary shows the level of demand needed to be part of the Keymark certification scheme and the technical expertise required in terms of data handling and data assessment within these laboratories. It is so much so, that all data provided in the aforementioned verifications shall be analysed by means of statistical calculations to be able to estimate the uncertainty of the test for the determination of the thermal conductivity, which in the case of ceis is of 1.9%.

Finally, to highlight the accuracy and precision of the laboratories within the Keymark scheme, attention should be drawn to this last piece of information showing the maximum deviation that ceis had in the last inter-laboratory comparative testing carried out within SDG-5 among all the Registered Laboratories which was of 0.5% with respect to the average value.

Therefore, Keymark is a voluntary certification mark that can be awarded together with national quality marks, since it provides quality added value owing to the high level of demand that it maintains and requires from all bodies integrating this certification scheme.

For more information, please visit the website: Keymark.